A car typically has one or two knock sensors. This number can vary depending on the make, model, and year of the vehicle.

Image Source: images.cars.com

Deciphering the Knock Sensor Count in Your Vehicle

Have you ever heard a strange pinging or knocking sound coming from your engine? This isn’t just an annoying noise; it’s a sign that something isn’t quite right. Modern cars have sophisticated systems to prevent this, and a key player in this system is the knock sensor. But how many of these vital components does your car actually have? Let’s dive deep into the world of engine knock and the sensors that keep it in check.

What is Engine Knock?

Before we talk about sensors, it’s important to grasp what “engine knock” or “detonation” is. In a gasoline engine, the fuel-air mixture is supposed to burn smoothly after the spark plug ignites it. However, sometimes, instead of burning evenly, pockets of the fuel-air mixture can ignite spontaneously due to excessive heat and pressure before the main flame front reaches them. This creates multiple shockwaves within the combustion chamber, resulting in that characteristic metallic pinging or knocking sound.

This uncontrolled combustion can put immense stress on engine components like pistons, connecting rods, and the crankshaft. Over time, severe or persistent engine knock can lead to serious internal engine damage.

The Role of the Knock Sensor

The primary job of a knock sensor is to detect these abnormal combustion events. Think of it as a sensitive microphone specifically tuned to the frequencies of engine knock. When it picks up the telltale vibrations, it sends an electrical signal to the engine control unit (ECU), also known as the Powertrain Control Module (PCM).

The ECU then interprets this signal and makes immediate adjustments to the engine’s timing. It typically retards the ignition timing, meaning the spark plug fires a little later. This reduces the pressure and temperature inside the combustion chamber, helping to prevent further detonation. The ECU can also adjust fuel delivery in some cases. These adjustments are crucial for protecting the engine and maintaining optimal performance.

How Many Knock Sensors Does a Car Typically Have?

The engine knock sensor count in a vehicle is not a one-size-fits-all answer. For many years, most cars were equipped with a single knock sensor. This sensor was usually mounted on the engine block, often in a central location where it could “hear” vibrations from multiple cylinders.

However, as engine technology advanced, particularly with the introduction of more cylinders and more complex cylinder head designs, manufacturers began using multiple knock sensors. In modern vehicles, especially those with V-engines (like V6, V8, V10, V12) or inline engines with many cylinders, it’s common to find two knock sensors. In these setups, each sensor might be responsible for monitoring a specific bank of cylinders or a group of cylinders. This allows the ECU to make more precise adjustments based on which part of the engine is experiencing knock.

So, to reiterate, while one knock sensor is the historical norm and still present in many vehicles, two knock sensors are increasingly common in today’s cars. Very rarely, some high-performance or specialized engines might have even more, but this is quite uncommon for everyday passenger vehicles.

Typical Knock Sensor Locations

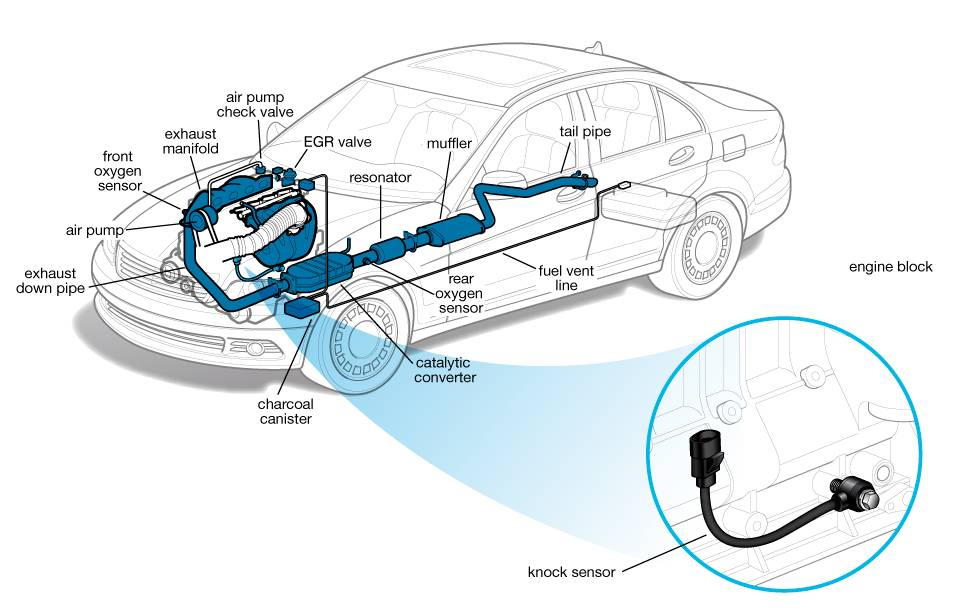

The physical placement of knock sensors is critical for their effectiveness. They need to be mounted directly onto the engine block or cylinder head where they can efficiently pick up the vibrations caused by detonation. Here are some typical knock sensor locations:

- On the Engine Block: This is perhaps the most common location. The sensor is often screwed into a threaded port on the side of the engine block, directly below the cylinders.

- On the Cylinder Head: Some manufacturers mount knock sensors on the cylinder head, often near the exhaust ports or in a central area between the cylinders.

- Between Cylinder Banks: In V-engines, a common placement for one or both sensors is on the valley pan or directly on the engine block between the two cylinder banks, allowing it to “listen” to both sides.

- Specific Cylinder Monitoring: In performance or highly engineered engines, you might find sensors positioned to monitor specific cylinders or pairs of cylinders more closely.

Identifying knock sensor quantity often involves visually inspecting the engine. Look for small, disc-shaped or cylindrical components, usually with a single wire connector, bolted to the engine block or cylinder head. They might be easily accessible or tucked away, requiring some searching.

Why the Variation in the Number of Knock Sensors?

The number of knock sensors in a vehicle is largely determined by the engine’s design and the manufacturer’s strategy for managing combustion.

- Engine Configuration: A simple inline-4 engine might only need one sensor to cover all its cylinders. A V8 engine, with its two banks of four cylinders, often benefits from two sensors, one for each bank, to pinpoint knock more accurately.

- Cylinder Head Design: The shape and layout of the combustion chambers and cylinder heads influence how vibrations travel. Multiple sensors can provide a more comprehensive “picture” of combustion activity.

- ECU Sophistication: More advanced ECUs can process data from multiple sensors simultaneously, allowing for finer control over ignition timing for individual cylinders or cylinder banks. This leads to better performance, fuel efficiency, and emission control.

- Cost and Complexity: While more sensors offer greater precision, they also add to the manufacturing cost and complexity of the vehicle’s wiring harness and engine management system. Manufacturers balance these factors when deciding on the engine knock sensor count.

How Many Detonation Sensors Does a Car Use?

The terms “knock sensor” and “detonation sensor” are often used interchangeably. Both refer to the component that detects abnormal combustion. Therefore, the answer to how many detonation sensors a car uses is the same as the engine knock sensor count: typically one or two for most passenger cars.

The Knock Sensor System Components

A knock sensor doesn’t operate in isolation. It’s part of a larger, integrated system. The key knock sensor system components include:

- Knock Sensor(s): The primary transducer that converts vibration into an electrical signal. These are often piezoelectric devices, meaning they generate a voltage when subjected to mechanical stress (vibration).

- Engine Control Unit (ECU/PCM): The “brain” of the engine. It receives the signal from the knock sensor, analyzes its frequency and amplitude, and then commands adjustments to ignition timing and sometimes fuel delivery.

- Wiring Harness: Connects the knock sensor(s) to the ECU. This harness must be robust to withstand the engine’s heat and vibrations.

- Engine Components: The physical parts of the engine that generate the vibrations, including the cylinder block, cylinder head, pistons, and connecting rods.

The knock sensor circuit function is straightforward: the sensor generates an AC voltage proportional to the intensity of the vibration. The ECU filters this signal to isolate the specific frequencies associated with knock and ignore other engine noise.

Detecting Engine Ping with Sensors

The ability to detect engine ping with sensors is what makes the knock control system so effective. Here’s how it works in practice:

- Normal Combustion: The spark plug ignites the fuel-air mixture. This creates a smooth pressure wave that travels through the combustion chamber. The knock sensor may register some low-level vibration, which the ECU ignores as normal engine operation.

- Detonation (Knock): If knock occurs, it creates a much sharper, higher-frequency vibration. The piezoelectric element in the knock sensor vibrates intensely in response.

- Signal Transmission: This vibration generates a small electrical voltage signal, which is sent through the wiring harness to the ECU.

- ECU Analysis: The ECU analyzes the frequency of the signal. Knocking typically produces vibrations in the 5 kHz to 15 kHz range, though this can vary by engine design. The ECU is programmed to recognize these specific frequencies.

- Timing Retard: If the ECU detects a signal within the knock frequency range and above a certain amplitude threshold, it interprets this as engine knock. It then commands the ignition system to retard the timing. For example, if the optimal timing was 10 degrees Before Top Dead Center (BTDC), the ECU might retard it to 5 degrees BTDC or even less.

- Feedback Loop: The ECU continuously monitors for knock. If the knock subsides after the timing adjustment, the ECU will gradually advance the timing back towards optimal levels to maintain performance and efficiency. This creates a dynamic feedback loop, constantly adjusting to prevent damage.

Common Knock Sensor Problems and Replacement

Like any automotive component, knock sensors can fail. Common issues include:

- Cracked housing: Physical damage can compromise the sensor’s integrity.

- Internal failure: The piezoelectric element can wear out or break.

- Wiring damage: The connector or wires can become corroded, frayed, or broken due to heat and vibration.

- Loose mounting: If the sensor isn’t securely fastened, it can’t properly detect vibrations.

When a knock sensor fails, the ECU often registers a Diagnostic Trouble Code (DTC), such as P0325 (Knock Sensor 1 Circuit Malfunction) or similar codes depending on the number of sensors and specific manufacturer.

Symptoms of a failing knock sensor can include:

- Check Engine Light: This is the most common indicator.

- Rough idling or poor performance: The ECU might be overly cautious and retard timing excessively, or it might fail to correct actual knock.

- Increased fuel consumption: Suboptimal ignition timing can reduce efficiency.

- Audible knocking or pinging: In some cases, the system may no longer be able to prevent knock.

Knock Sensor Replacement Guide

Replacing a knock sensor is a task that many DIY mechanics can tackle, but it requires careful attention. Here’s a general outline of a knock sensor replacement guide:

- Safety First: Ensure the engine is cool. Disconnect the negative battery terminal to prevent electrical shorts.

- Locate the Sensor: As discussed earlier, find the faulty knock sensor. You might need to consult your vehicle’s service manual for precise location.

- Access the Sensor: This can sometimes be challenging. You may need to remove air intake components, heat shields, or other parts to gain access.

- Disconnect the Electrical Connector: Carefully unclip and remove the wiring harness connector from the sensor.

- Remove the Old Sensor: Use the appropriate socket or wrench to unscrew the old sensor from the engine block or cylinder head. Be prepared for a small amount of residual oil or coolant.

- Prepare the New Sensor: Some new knock sensors come with sealant pre-applied to the threads. If yours doesn’t, you might need to apply a small amount of thread sealant specifically designed for high-temperature automotive applications. Crucially, do not get sealant on the sensing element of the sensor.

- Install the New Sensor: Screw the new sensor into the mounting port. Tighten it to the manufacturer’s specified torque. Overtightening can damage the sensor or the engine block, while undertightening can prevent proper function.

- Reconnect the Electrical Connector: Securely attach the wiring harness connector to the new sensor.

- Reassemble: Reinstall any components that were removed for access.

- Reconnect Battery and Test: Reconnect the negative battery terminal. Start the engine and check for any warning lights. A test drive might be necessary to confirm the issue is resolved.

- Clear Codes: Use an OBD-II scanner to clear any stored DTCs related to the knock sensor.

Important Note: If your vehicle has multiple knock sensors, it’s often best to replace them in pairs if one has failed, or at least confirm which specific sensor the DTC is pointing to.

Universal Knock Sensor Applications

While most knock sensors are designed specifically for a particular vehicle model or engine family, there are some universal knock sensor applications to consider.

- Aftermarket Systems: In some custom vehicle builds or older vehicles where original parts are scarce, mechanics might use universal or generic knock sensor kits. These kits usually include a sensor that can detect a broad range of knock frequencies and may require specific calibration or wiring to integrate with a non-factory ECU.

- Testing and Diagnosis: Universal sensors can also be useful for diagnostic purposes. If a mechanic suspects a knock issue but the original sensor is difficult to access or test, a universal sensor might be temporarily fitted to see if it can detect knock.

However, for most vehicle owners, sticking with OEM (Original Equipment Manufacturer) or high-quality aftermarket sensors designed for their specific car is the most reliable approach.

Conclusion: The Importance of Knowing Your Knock Sensor Count

The engine knock sensor count is a small detail that plays a significant role in your car’s health and performance. Whether your car has one or two, these sensors are the guardians against damaging detonation. By detecting engine ping with sensors, they allow the ECU to make vital adjustments, keeping your engine running smoothly and protecting it from harm.

Regular maintenance and paying attention to your Check Engine light can help ensure these crucial components are functioning correctly. If you suspect an issue, consulting a qualified mechanic or referring to your vehicle’s service manual is always the best course of action. Knowing the basics of your knock sensor system components and their function empowers you as a car owner and helps keep your vehicle in top condition.

Frequently Asked Questions (FAQ)

Q1: Can a car run with a bad knock sensor?

A1: Yes, a car can typically run with a faulty knock sensor. However, the engine’s computer (ECU) will lose its ability to detect and correct engine knock. This can lead to reduced engine performance, decreased fuel efficiency, and, if knock persists, potential engine damage over time. The Check Engine Light will usually illuminate.

Q2: How do I know if my knock sensor is bad?

A2: Common signs of a bad knock sensor include the Check Engine Light being on, a rough idle, reduced engine power, and possibly audible engine knocking or pinging. Your mechanic can diagnose a faulty knock sensor using an OBD-II scanner and testing the sensor directly.

Q3: Can I drive with a Check Engine Light on that indicates a knock sensor issue?

A3: It’s generally not recommended to drive for extended periods with a Check Engine Light on due to knock sensor issues. While the car may seem to run fine initially, the lack of knock detection means the engine is vulnerable to damage. It’s best to have it inspected and repaired as soon as possible.

Q4: Do all cars have knock sensors?

A4: Nearly all modern gasoline-powered cars and trucks manufactured within the last 25-30 years are equipped with knock sensors. Older vehicles or some very basic engines might not have them, but they are standard on virtually all vehicles equipped with electronic fuel injection and computer-controlled ignition systems.

Q5: What happens if the knock sensor is over-tightened?

A5: Over-tightening a knock sensor can damage its internal components (like the piezoelectric crystal) or strip the threads in the engine block or cylinder head. This can render the sensor ineffective and may require costly repairs to the engine block. Always use a torque wrench if specified in your vehicle’s service manual.